Manufacturing performance is built on movement. Every part has to arrive, align, and lock into place at the right moment. When one of those motions drifts out of sync, the whole line feels it: output drops, teams chase problems, and a process that used to feel smooth suddenly fights back.

Today’s challenge isn’t just running faster. It’s running faster without adding strain on operators, sacrificing quality, or making changeovers painful. The most resilient plants solve this by designing lines around robotic assembly from the start – not bolting on automation later.

When high-speed pick-and-place, vision-guided positioning, and precise joining are engineered into the base machine, speed becomes stable speed. Throughput rises, quality holds, and the line keeps pace with real-world demand.

Where Production Breaks Down

Most manufacturers face the same pressures:

- Labor is tight. It’s harder to staff repetitive stations and keep skilled operators on every shift.

- Unplanned downtime is expensive. In high-throughput environments, a few unplanned minutes quickly turn into missed orders and overtime.

- Part variability is real. Bottles, closures, and molded parts rarely arrive in perfect shape or orientation. Small inconsistencies turn into jams, rework, or quality drift.

- Manual inspection can’t keep up. At higher speeds, even strong operators miss defects and codes that a vision system would catch.

- Alignment and transfer are often the weak link. Lines that look good on paper get tripped up by how parts are actually presented, moved, and handed off.

Robotic assembly is designed to absorb those realities instead of fighting them.

Robotic Assembly: The Foundation of Stable Throughput

Norwalt designs equipment for real plant conditions – where parts can be slightly warped, off-center, or loosely controlled upstream. Instead of asking operators to compensate, robotics and precision part handling do the heavy lifting.

- Every transfer and placement is controlled.

- Orientation is corrected on the fly.

- Speed increases without opening up the process window.

The result is a line where high speed doesn’t mean “more fragile.” It means more predictable.

What Robotic Assembly Looks Like on the Line

Integrated Handling for Real-World Parts

Robotic handling systems stabilize and orient parts before they reach critical stations. Rather than relying on gravity rails and luck, robots:

- Correct part orientation

- Manage variability in shape and size

- Prevent slowdowns caused by inconsistent presentation

High-Speed Pick and Place

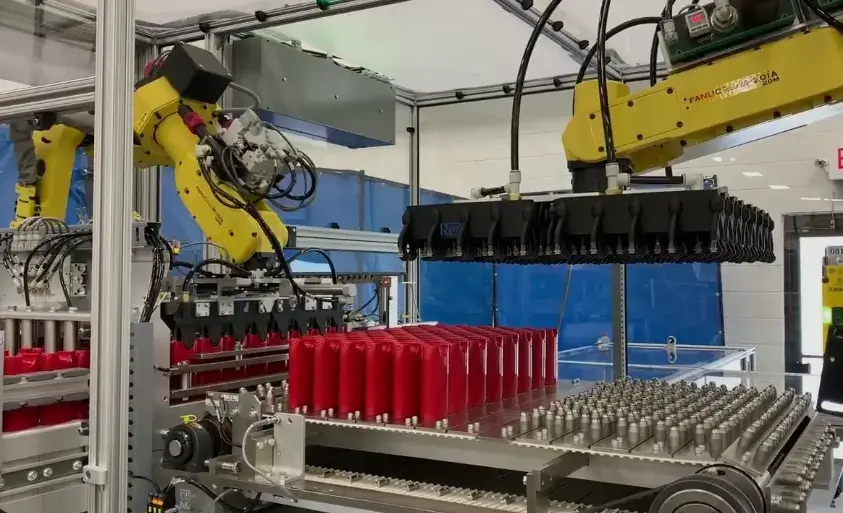

- Layer packers place products into trays or cases at up to 800 parts per minute, with tooling that can swap patterns quickly for new formats.

- Puck loaders and depuckers handle asymmetric or orientation-critical containers at over 600 parts per minute, making sure every bottle or component is correctly presented for downstream filling, assembly, or printing.

End-of-arm tooling, often produced via 3D printing, is tailored to each product so the line can support new SKUs without a complete rebuild.

Robotics Designed Around Part Handling

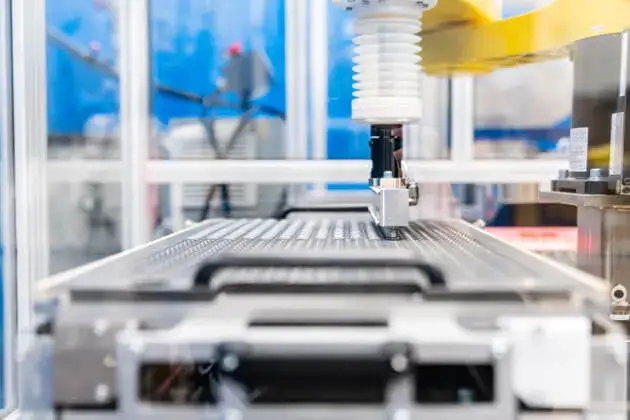

In Norwalt systems, high-speed part movement is a primary design constraint, not an afterthought. Robots deliver parts to each station at the correct:

- Angle

- Height

- Position

- Timing

This protects throughput, reduces micro-stoppages, and keeps downstream equipment running in its ideal window.

Assembly for Complex Products

For products that require precise insertions or tight tolerances, robotic cells combine:

- 2D and 3D vision for part location and orientation

- Force sensors to feel insert depth and resistance

- Post-assembly verification to confirm correct fit, presence, and alignment

That combination allows robots to do jobs that historically depended on skilled, highly trained operators – and to do them at line speed.

Why This Matters

Robotic assembly directly attacks the most common reasons lines underperform:

- Inconsistent part presentation

- Operator fatigue and turnover

- Misalignment between stations

- Quality drift over long runs

It’s not an accessory bolted onto a conveyor. It’s the foundation that converts theoretical speed into real, repeatable performance on the floor.

Common Robotic Systems and Applications

Norwalt brings robotics, vision, and intelligent control together in custom systems for high-volume, high-precision manufacturing.

Joining and Welding

Automated joining modules can include:

- Induction welding

- Conduction welding

- Ultrasonic welding

These processes can be combined with leak testing, decorating, lining, and vision inspection in a single cell, reducing manual handling and secondary operations.

High-Speed Pick and Place

- Layer Packers – Robotic layer packers place products into trays or shippers at up to 800 ppm, handling a wide range of shapes and sizes with quick-change tooling.

- Puck Loaders / Depuckers – For orientation-critical containers, puck systems run above 600 ppm while keeping every part in the right position for filling, capping, or printing.

Vision-Guided Robotic Systems

Vision-guided robotics reduce labor demands and improve consistency:

- 2D and 3D cameras locate parts and verify orientation

- Force sensors handle difficult insertions without damage

- Post-assembly and post-print verification confirm output before it moves downstream

Inspection can include laser measurement, cosmetic checks, barcode and 2D code reading, fill level, ovality, and more – offered as fully integrated solutions, standalone units, or field upgrades.

Sensing, Guidance, and Quality Control

Sensing Technologies

Robotic sensing is central to precision:

- Force sensing lets robots feel when a part is fully seated.

- Vision and laser scanning determine part position, orientation, and readiness before the next motion.

Guidance Systems

Guidance mechanisms keep products in the right place at the right time:

- Puck systems orient and stage containers for filling, assembly, or direct-to-object printing.

- Layer packers position items quickly and repeatably, using custom end-of-arm tooling.

Built-In Quality Control

Integrated vision inspection protects quality from start to finish:

- Defect and cosmetic inspection

- Fill height and presence/absence checks

- Barcode and date-code verification

- Assembly verification and dimensional checks

Bad parts are removed in real time instead of becoming downstream rework.

Robotic Sorting and Flow Management

Norwalt systems handle sorting and flow management while parts are in motion:

- Orientation and shape recognition

- Tray or case placement

- Barcode and code-based routing

- Size, color, or configuration sorting through vision classification

This keeps high-speed lines organized without additional manual touchpoints.

The Next Move for a Stronger Production Line

The pressure to build more, with more variation, using smaller teams isn’t going away. The manufacturers that stay ahead will be the ones who design around stability first and then layer on speed.

Robotic assembly provides that stability. It:

- Absorbs upstream variability

- Protects critical tolerances

- Strengthens quality checks

- Unlocks higher, more reliable throughput

From high-speed layer packers and puck loaders to vision-guided assembly and direct-to-object printing cells that combine robotics, vision, and analytics, Norwalt helps manufacturers engineer precision into every movement of the line.

When robots, vision, and intelligent control work together, the result is a line that’s more predictable, more efficient, and ready for whatever the next product launch, promotion, or demand spike brings.